- corrugated carton Printer slotter die cutter machine

- hardboard production line

- partition assembler machine

- carton folder gluer machine

- Ink Waste Water Treatment Machine

- paper angle board machine

- paper making production line

- Paper tube making machine

- paper making production line

- Full automatic die cutting machine

- Slotting machine

- stacking machine

- thin blade machine

- Paper coating machine

-

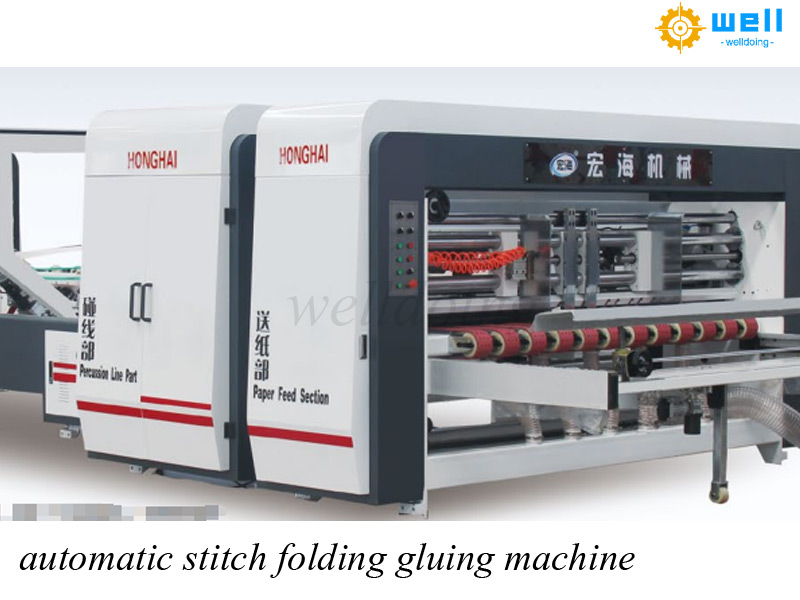

automatic carton box nail folding gluing equipment

1. parts:

paper feeding part, line touching part, folding part, nailing box part, counting output part and electrical control part

2. Automatic feeding, automatic line, automatic folding, automatic correction, automatic nailing, automatic counting, automatic stacking output

3. when the adjustment more convenient, fast and efficient

4. Advanced technology, reliable quality.

-

double chip automatic box stitching machine

Name: Double chip full automatic box stitching machine Model: SQDJ-2500 Mechanical speed: 700-800 nails per minute; Applicable to corrugated board three layers, five layers, seven layers (seven layers need special instructions).

-

automatic carton box folder gluer stitching machinery

1. parts:

paper feeding part, line touching part, folding part, nailing box part, counting output part and electrical control part

2. Automatic feeding, automatic line, automatic folding, automatic correction, automatic nailing, automatic counting, automatic stacking output

3. when the adjustment more convenient, fast and efficient

4. Advanced technology, reliable quality.

-

automatic corrugated box folder gluer stitcher machine

paper feeding part, line touching part, folding part, nailing box part, counting output part and elecrical control part. PLC control touch screen input data, nail box part action servo motor control, simple and reliable operation. Automatic feeding, automatic line, automatic folding, automatic correction, automatic nailing, automatic counting, automatic stacking output, before and after the whole machine

-

Manual double servo stitcher machine

1.Schneider france original import four servo motor drive ,high precise with few mechnical driving part ,reduce the machine damage

2.box stitching machine wenlun touch screen ooperation the parameter ( nail distance, nail unmber,nail types,tial gate ) change convinently

3.The box stitching machine control system use the omron plc control system -

Corrugated carton double servo manual stitching machine

1. Schneider france original import four servo motor drive ,high precise with few mechnical driving part ,reduce the machine damage

2. box stitching machine wenlun touch screen ooperation the parameter ( nail distance, nail unmber,nail types,tial gate ) change convinently

3. The box stitching machine control system use the omron plc control system. -

Semi-automatic carton box stitching machine

Main partr and function introduction : 1. Schneider france original import four servo motor drive ,high precise with few mechnical driving part ,reduce the machine damage 2 box stitching machine wenlun touch screen ooperation the parameter ( nail distance, nail unmber,nail types,tial gate ) change convinently 3 The box stitching machine control system use the omron plc control system 4..back electrical baffle use the stepper motor driven ,size accurate ,size changing is more convine...