Corrugated carton double servo manual stitching machine - Welldoing trading limited

Semi-automatic carton stitching machine main part and function introduction :

1. Schneider france original import four servo motor drive ,high precise with few mechnical driving part ,reduce the machine damage

2 box stitching machine wenlun touch screen ooperation the parameter ( nail distance, nail unmber,nail types,tial gate ) change convinently

3 The box stitching machine control system use the omron plc control system

4..back electrical baffle use the stepper motor driven ,size accurate ,size changing is more convinent

5.The contactor in the control box adopt simense brand

5 .Display and circuit breaker adopt schneider ,pohto electric switch and proximity switch adopt omron branch .

6. Bottom mould and blade adopt japan tungsten steel

7. Whole stiching head adopt special steel to make , computer digital processed

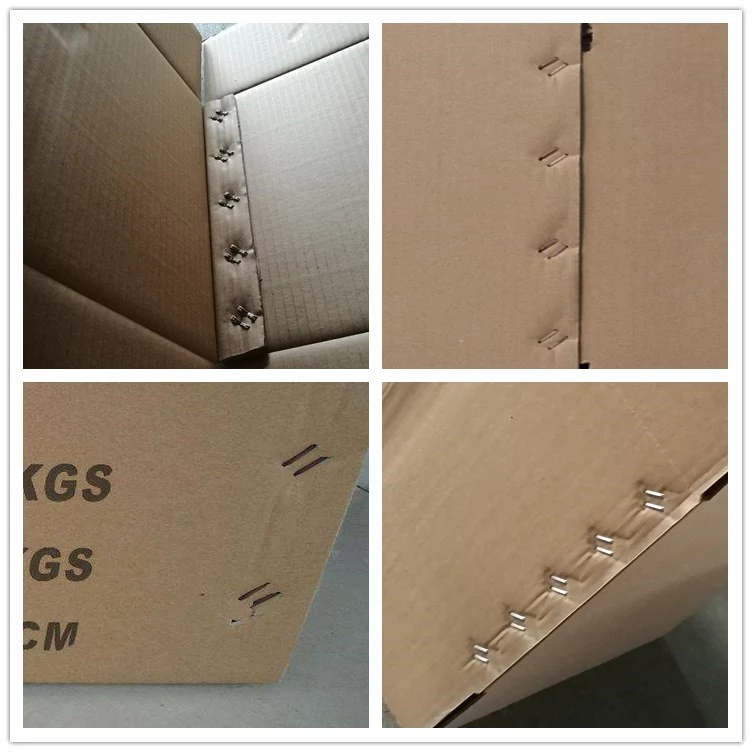

8 .The box stitching machine have single nail ,double nail, strenght nail

1.Main Technical paramteters for semi automatic box stitching machine

Hi-speed semi automatic stitching machine is the specified machine used in the last process in corrugated carton box making ,we can do manual type carton stapler , semi auto type carton stapler and fully auto type carton stapler .

Manual servo model double head carton stitching machine

Can do single nail , double nail and strengthen nail complete in one time , can be suitable for different kinds of customer requirements of stitching

Three design stapler machine we have

Stitcher machine description

Our carton box stitching machine use the servo motor and drive emergency stop ,emergency start advantage instead of the clutch ,increase the machine accurate and use life .

2.have speed adjust function 150-450stapler /min speed adjust ,so not control worker skill .

3.Machine head structure easy ,and convenience maintain ,knives use the alloy steel connect bar use the bear connect ,reduce wear ,and increase use life .

4.It can do single nail , double nail and strengthen nail complete in one time , can be suitable for different kinds of customer requirements of stitching .

5.Size 600mm,1200mm,1400mm,1600mm,1800mm,2000mm

6.Speed 150-450nail/min

6.wire proper : 16#17#.18#

7. power : 220volt 800w

| Model | Stapling speed | Stapling thickness | Stretching length of the loading arm | Exterioe demension | Weight |

| DX-600 | 250s/min | 3/5 ply | 600mm | 1100x600x1760 | 300kg |

| DX-900 | 250s/min | 3/5/7ply | 900mm | 1400x600x1760 | 400kg |

| DX-1200 | 250s/min | 3/5/7ply | 1200mm | 1700x700x1820 | 600kg |

| DX-1400 | 250s/min | 3/5/7ply | 1400mm | 1900x700x1820 | 800kg |

| DX-1800 | 250s/min | 3/5/7ply | 1800mm | 2300x700x1820 | 1000kg |

1.Stitching machines function

Stitching the corrugated cardboard to finished corrugated box

2.Two design for semi auto Stitching machines corrugated box

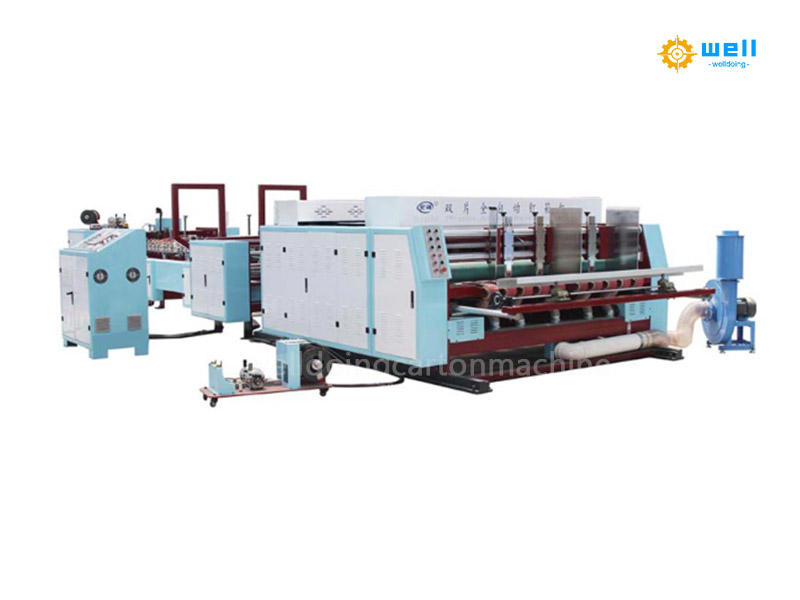

Design one – single piece stitching machine

Characters :

1)Imports of dual-servo-driven precision , mechanical transmission part of the reduction can effectively reduce the mechanical failture rate .

2)Touch screen operation , parameters (Screw pitch , the number of nails , nail species , tailgate) transformation convenient .

3)Siemens PLC control system for the hole control system

4)After the electric tailgate , the use of stepper motor drive, accurate size , transform size is more concenient

5)Bottom die , tungsten steel blade made by Japan (wear)

6)Nail line alarm after use (To avoild leakage ariting without nail line play , bad for small nail)

7)Mechanical speed :500nails/min

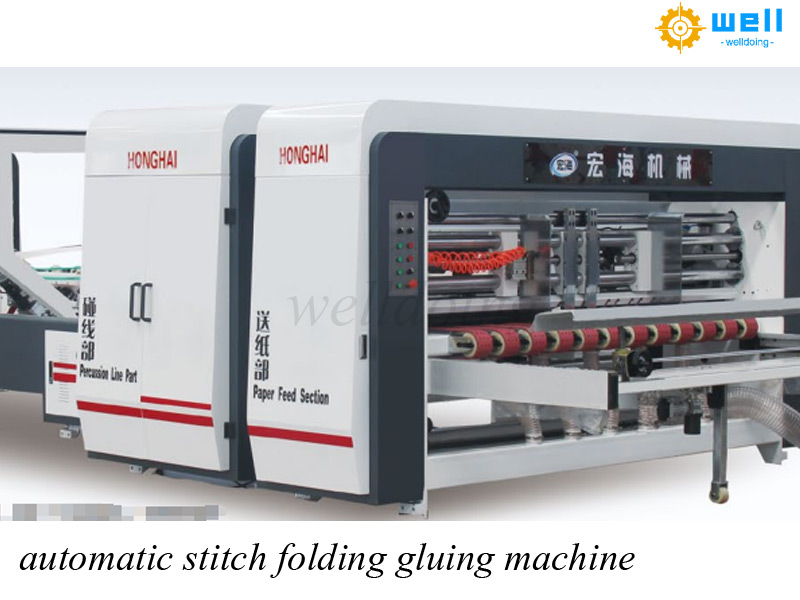

Feature:manual servo model double head box stitching machine for corrogated cardboard carton box

1 A dual-purpose machine for single forming carton, double forming carton, irregular carton.

2. The size is full electrically controlled and it can be changed the size in 2-3min

3. The strengthened, single, double nailing can be finished in a lump.

4.. Auto counting, after stacked, it will be auto packing.

5. Available for large carton, and nail-feeding is high speed and high efficiency

6. Nail from is free adjustable between 30-120mm, set by computer

7. It can do special box without cover

Use and Characteristics:servo control stitching machine for corrogated cardboard carton box

1. It can nail single nail double nail, strengthen nail completed in one-time, can be suitable for different kinds of customer requirement of nail.

2. It can be changed size quickly in one time, can be operated easily and not had to experience.

3. Paper feeding section can automatic counting, send after the bundle into the bundle.

4. It is man-machine interface control for convenient operation.

5.Back-automatic counting. The finished products done can be sent to the end of conveyor by setting the number(1-99)

servo control stitching machine for corrogated cardboard carton box

| Model | Stapling Speed | Stapling Thickness | Exterior Dimension | Weight |

| DX-600 | 250 s/min | 3/5 ply | 1100x600x1760 | 300kg |

| DX-900 | 250 s/min | 3/5/7 ply | 1400x600x1760 | 400kg |

| DX-1200 | 250 s/min | 3/5/7 ply | 1700x700x1820 | 600kg |

| DX-1400 | 250 s/min | 3/5/7 ply | 1900x700x1820 | 800kg |

| DX-1800 | 250 s/min | 3/5/7 ply | 2300x700x1820 | 1000kg |

Technical parameter :

| Model and parameter | SDJ-2400 | SDJ-3000 |

| Max corrugated paperboard(A+B)x 2 (mm) | 4800 | 6000 |

| Min. corrugated paperboard(A+B)x 2 (mm) | 1060 | 1060 |

| Max paperboard length mm | 2850 | 2850 |

| Min. paperboard length mm | 350 | 350 |

| Max. paperboard width mm | 1200 | 1500 |

| Min. paperboard width mm | 180 | 180 |

| Min. paperboard height(C+D+C) mm | 400 | 400 |

| Nail distance mm | 30-120 | 30-120 |

| Number of nails. | 1-99 | 1-99 |

| Nails speed nails/min | 300 | 300 |

| Max (L+W)*2 | 2460mm | Power | 4HP |

| Min (L+W)*2 | 606mm | Length | 2800mm |

| Max (L+W)*2 | 2460mm | width | 2600mm |

| Min (L+W)*2 | 606mm | Weight | 2000kg |

| Height of feeder | 900mm | Stitching pitch | 30-100mm |

| Speed | 400/stitches/min | Number of stitching | 1-99 stitches |

The main function and components

Can nail a single nail, two nail,strengthen nail one time.

One minute quick change size. Easy operation without experience.

Paper feeder can count automatically. Tied into buldles sent.

Omron PLC control system.

Chint contacts.

Taiwan electromagnetic clutch,

All switch control box using domestic brands.

From Stapling to the semi-finished products to finished goods, only two people is OK. Simple operation and reduced salary.

Automatic accounting after the segment, the number of sheets can do a good job of setting the number of products(1-99) sub-stack convey is not sent to client.

It can be covered nails whether with covering or without covering.

The use of touch-screen control, nail away from the touch screen can be set directly facilitate the operation.