- hardboard production line

- partition assembler machine

- carton folder gluer machine

- Ink Waste Water Treatment Machine

- paper angle board machine

- paper making production line

- Box stitching machine

- Paper tube making machine

- paper making production line

- Full automatic die cutting machine

- Slotting machine

- stacking machine

- thin blade machine

- Paper coating machine

-

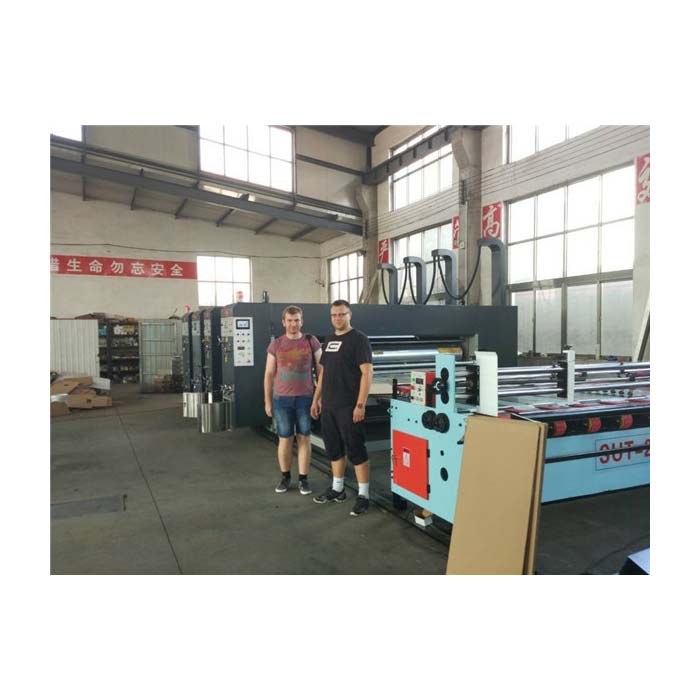

automatic flexo printer slotter die cutter stacker machine

Human-machine interface, order storage, easy to operate.

Using 20CrMuTi alloy steel gear, carbon seepage quenching treatment, tooth grinding processing, six grade precision, maintain long-term color cover precision.

The whole shaft and roller are made of seamless steel pipe, fine grinding and hard surface coating.

Main machine, fan adopts frequency conversion control, start, operation is more stable, more energy saving -

corrugated cardboard flexo printing die cutting slotting machine

corrugated carton printing slotting die cutting machine ◆ the whole machine is fast order changing and easy to operate. ◆ adopt imported PLC and touch screen multi-function control. Common orders can be stored to speed up the order replacement operation. ◆ all roller shafts are chrome plated, ◆ the transmission adopts alloy steel precision grinding gear and spray circulating lubrication system. ◆ key free continuous ring is applied to reduce center wear, virtual position amplification ... -

lead edge feeder flexo printing slotting die cutting machine

corrugated carton flexo printing slotting machine ◆ the whole machine is fast order changing and easy to operate. ◆ adopt imported PLC and touch screen multi-function control. Common orders can be stored to speed up the order replacement operation. ◆ all roller shafts are chrome plated, ◆ the transmission adopts alloy steel precision grinding gear and spray circulating lubrication system. ◆ key free continuous ring is applied to reduce center wear, virtual position amplification and small pri... -

corrugated cardboard flexo printing die cutting slotting machine

Functions and features of the corrugated carton 3 color printer die cutter slotter machine : ● the electrical appliances and computer software of the whole machine are made of Schneider, Omron and Siemens. Stable and reliable quality; It adopts man-machine interface and computer order management, which is easy to operate. ● the wallboard and important parts of the whole machine are subject to aging treatment and tempering to eliminate metal internal stress; CNC grinding machines are made of h... -

corrugated carton 1-4 color printer die cutter slotter machine

corrugated carton box printing die cutting slotting machine Paper feeding section (one group) 1. Machine clutch: 1) An alarm bell is attached to the clutch of the electric control machine, and the alarm bell is continuously sounded during the travel to ensure the safety of the operators. 2) Pneumatic interlocking device, locking firmly, convenient and accurate. 3) The main motor adopts variable frequency motor and variable frequency controller, which can save energy and start stably. The moto... -

automatic flexo printing die cutting slotting machine

automatic flexo printing die cutting slotting machine 1. Die cutting shaft alignment gauze shaft alignment makes the machine run more easily. 2. The circumferential direction of the master roll and the die-cutting part adopts computer (PRC) rapid phase 360 ° adjustment and computer display to improve work efficiency (orders can be stored and executed arbitrarily). The input dimension phase is automatically adjusted. 3. It is equipped with automatic counting device, which can correctly contro... -

Lead eder feeder flexo printer die cutter slotter machine

The leading edge sucks air for paper feeding, the steel pipe surface of the upper paper feeding roller is wrapped with wear-resistant rubber, and the surface of the lower paper feeding roller is wrapped with wear-resistant rubber

Embossing and hard chromium plating, balance correction, more stable paper feeding, high degree and simple operation

-

4 color flexo printer slotter die cutter machine

Functional features:

1. The advanced adsorption leading edge paper feeding system has the advantages of simple operation, high speed and high precision.

2. The wallboard and important parts of the whole machine are subject to aging treatment and tempering to eliminate metal internal stress; They are made by high-precision machining center and grinded by NC grinder.

3. All transmission rollers are made of seamless steel pipe, with ground surface and hard chromium plating. The transmission gear is made of 45# steel and quenched with high frequency.

4. The gear of the whole machine is equipped with oil pump lubrication system to increase the service life of the gear.

-

semi-automatic printing slotting die cutting machine

1. The main functions and uses of the carton printing slotting machine Carton printing and slotting machine This machine can complete the functions of printing, slotting, edge separation and crimping of corrugated cardboard at one time. It has the advantages of exquisite printing, high precision and fast efficiency. The adjustment range of each adjustment mechanism is large, and it can be adapted to three, five and seven layers of cardboard. Technical parameters of CN102-1425 two-color printi... -

automatic printing slotting die cutting machine

1. The whole machine is designed and manufactured in accordance with high requirements and reliable functions. The user-friendly design of the whole machine can be set, corrected, executed and function in a short time, and displayed with accurate data. To 2. Advanced adsorption leading edge paper feeding system, simple operation and high precision. To 3. All drive rollers are made of steel, plated with hard chrome, and the surface is ground. The transmission gear is made of alloy steel, heat-...