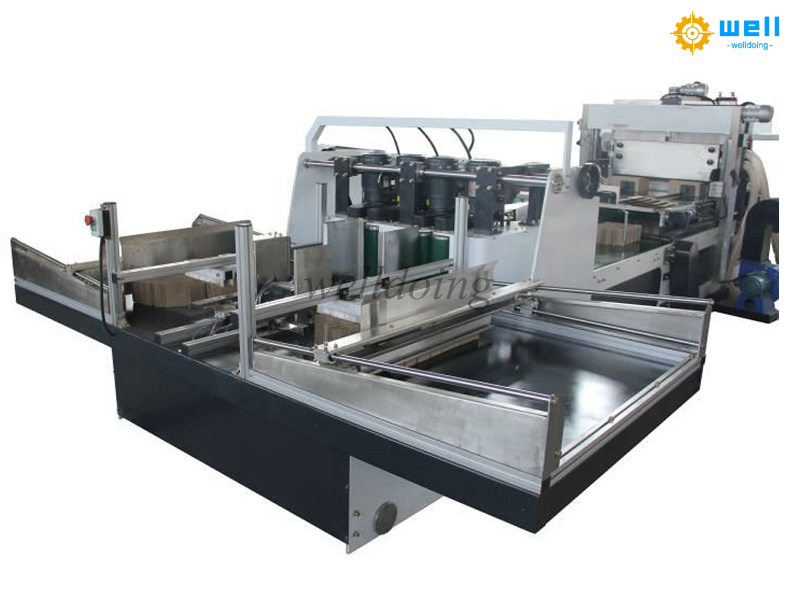

Full automatic flat bed die cutting machine - Welldoing trading limited

full automatic flat bed die cutting machine

Stripping Section:

The waste removal form-work adopts the central positioning system, which is automatically clamped, which is fast and convenient for plate alignment.

Front Feed Section:

The full automatic paper feeding die cutting machine adopts the structure of the combination of the air suction box, the paperboard, the supporting bar and the air discharge cylinder to effectively prevent the printing surface from being scratched and scratched.

Variable frequency control and air volume regulation can meet the paper feeding requirements of various corrugated products with a thickness of 1-9mm.

Side Position Part Of Paper Feeding Table:

The patented servo motor control ensures the accurate positioning of the mentally retarded and the flat front edge. A set of side positioning push gauges on the left and right to ensure accurate positioning of the paperboard.

Electrical Section:

PLC control, safer and more reliable. The electric control system is controlled by PLC and equipped with various safety protection devices. In case of failure, it will give an audible and visual alarm and stop automatically to truly ensure the safety of fully automatic die cutting machine.

| Type | 1300X | 1480X | 1650X | 1880X |

| Max. Paper size | 1330×980(mm) | 1480×1080(mm) | 1650×1210(mm) | 1880×1420(mm) |

| Min. Paper size | 550×480(mm) | 550×480(mm) | 650×550(mm) | 650×550(mm) |

| Max. Cutting size | 1300×960(mm) | 1450×1050(mm) | 1620×1190(mm) | 1850×1400(mm) |

| Max. Cutting pressure | 250×104N | 300×104N | 300×104N | 300×104N |

| Stock range | Corrugated≤9mmCardboard≥250g | Corrugated≤9mmCardboard≥250g | Corrugated≤9mmCardboard≥250g | Corrugated≤9mmCardboard≥250g |

| Cutting precision | ±0.5(mm) | ±0.5(mm) | ±0.5(mm) | ±0.5(mm) |

| Max. Mechanical speed | 4200s/h | 4200s/h | 3600s/h | 3000s/h |

| Pressure adjusting range | ±1(mm) | ±1(mm) | ±1(mm) | ±1(mm) |

| Min. Gripper Margin | Gripper ≥8(mm) | Gripper ≥8(mm) | Gripper ≥8(mm) | Gripper ≥8(mm) |

| Total Power | 30.03kw | 34.03kw | 34.03kw | 38.5kw |

| Machine dimension(include the work platform) | 6870×4510×2292(mm) | 6950×4650×2292(mm) | 7333×4820×2330(mm) | 8235×5637×2600(mm) |

| Machine dimension(exclude the work platform) | 6392×2450×2292(mm) | 6587×2596×2292(mm) | 6926×2802×2330(mm) | 7993×3035×2600(mm) |

| Gripper/needle numbers/each | 10 | 11 | 12 | 14 |

| Total Weight |  ̄18.5t |  ̄22t |  ̄23t |  ̄29t |

| Type | 1300QX | 1480QX | 1650QX | 1880QX |

| Max. Paper size | 1330×980(mm) | 1480×1080(mm) | 1650×1210(mm) | 1880×1420(mm) |

| Min. Paper size | 550×480(mm) | 550×480(mm) | 650×550(mm) | 650×550(mm) |

| Max. Cutting size | 1300×960(mm) | 1450×1050(mm) | 1620×1190(mm) | 1850×1400(mm) |

| Max. Cutting pressure | 250×104N | 300×104N | 300×104N | 300×104N |

| Stock range | Corrugated≤9mmCardboard≥250g | Corrugated≤9mmCardboard≥250g | Corrugated≤9mmCardboard≥250g | Corrugated≤9mmCardboard≥250g |

| Cutting precision | ±0.5(mm) | ±0.5(mm) | ±0.5(mm) | ±0.5(mm) |

| Max. Mechanical speed | 4200s/h | 4200s/h | 3600s/h | 3000s/h |

| Pressure adjusting range | ±1(mm) | ±1(mm) | ±1(mm) | ±1(mm) |

| Min. Gripper Margin | Gripper ≥8(mm) | Gripper ≥8(mm) | Gripper ≥8(mm) | Gripper ≥8(mm) |

| Total Power | 31.03kw | 35.29kw | 35.5kw | 41.5kw |

| Machine dimension(include the work platform) | 8330×4510×2292(mm) | 8594×4650×2292(mm) | 8855×4820×2330(mm) | 10067×5637×2600(mm) |

| Machine dimension(exclude the work platform) | 7713×2450×2292(mm) | 8009×2596×2292(mm) | 8449×2802×2330(mm) | 9820×3035×2600(mm) |

| Gripper/needle numbers/each | 10 | 11 | 12 | 14 |

| Total Weight |  ̄20.5t |  ̄24t |  ̄27t |  ̄31.5t |

Products Advantages:

1.Top quality

2.Large output

3.Delivery timely

4.Competitive price

5.Satisfying service

6.Old and experienced factory

WELLDOING TRADING Co. Ltd. is a manufacturer + sales and after-sales company, which is mainly engaged in large-scale semi-automatic chain-bar water-based printing machine,automatic flexo printer slotter die cutter stacker machine , high-speed high-definition paper box printing and slotting die-cutting machine, 2 layers corrugated production line, box-sticking machine, Tying Machine ,automatic partition assembler machine ,paper tube making machine, flexo ink printing wastewater treatment machine, EPE foam tube making machine and so on.

Due to the large size and weight of the equipment, we generally ship by sea. Each machine will be fixed in the container. Also we can wrap it according to customer’s requirements.