1600mm 4ply grey board production line - Welldoing trading limited

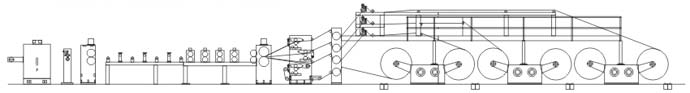

The automatic 4 ply grey board production line is mainly composed of paper rack, bridge conveyor, glue coating machine, compactor, drying plate drying cadres, cooling department, vertical and horizontal cutting machine, etc. It has the characteristics of advanced production technology, reasonable design, convenient operation and maintenance, safety and reliability, energy saving and no environmental pollution. grey board paper making machine Can compound three layers, four layers, five layers, six cardboard, the thickest up to 3.5mm, is a new type of carton, carton, high-grade gift box, stationery and other packaging materials specifications: 1200mm-2000mm.

The 1600mm grey board production line applys to laminating 2-4 ply materia! weight of 300-600g/ m2〇 The machine is composed mainly of stand, bridge conveyor, gluer, compactor press,(platform) dryer, cooler, thin blade slitter scorer, CNC cutting machine and stacker. With characteristics of advanced production engineering, easy operation and maintenance,safe and steady, energy saving and environment friendly. Size 1200mm~2200mm are optional, quantified 2000g/m2, thickness 3.5mm, through put 35T-80T/D. The the thickness, tightness, moisture content, smoothness, stiffness and tensile strength can reach the standard of the imported products. Which can eventually replace the imported corrugated board, which suit for the cigarette box, wine box, food box, hard book cover, High-end gift box and stationery. The high speed hardboard production line makes up for many defects of the manual laminator,greatly reduced the cost of production, improved the quality of production, increased the economic efficiency. It is your ideal choice to product corrugated board and carton boxes.