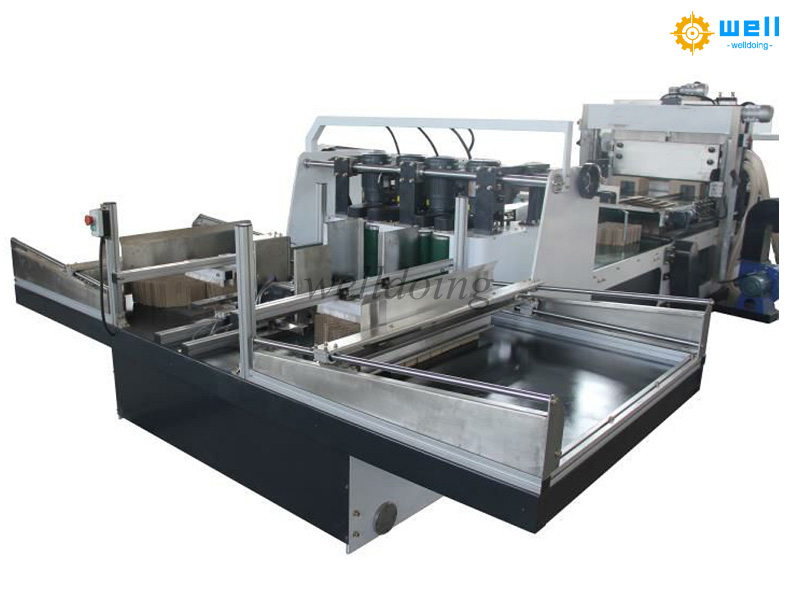

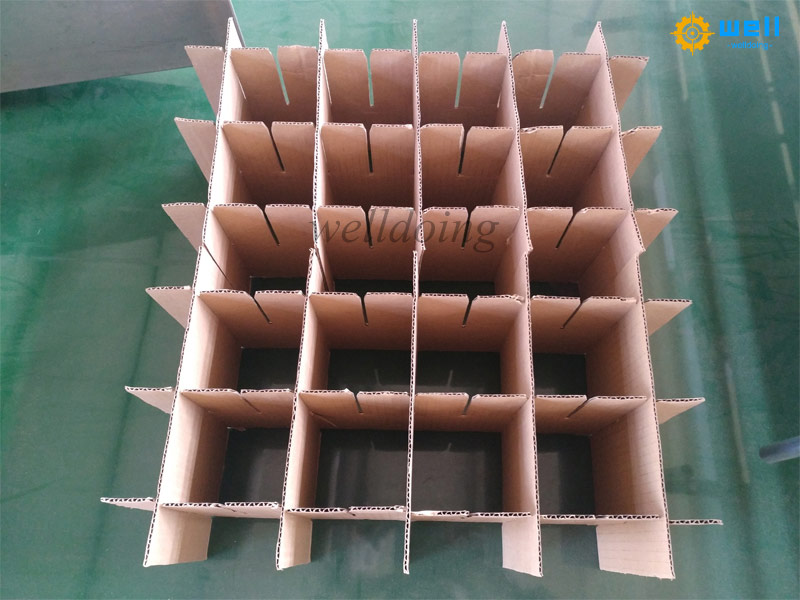

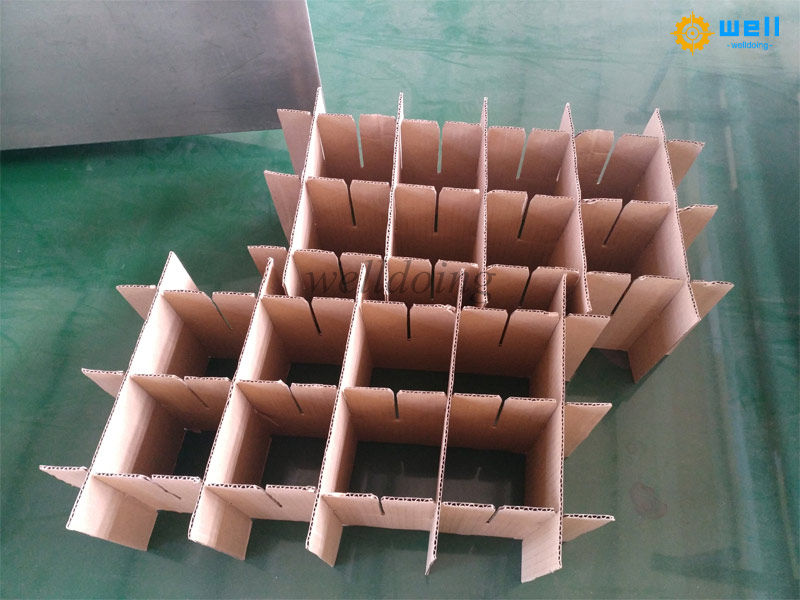

What are the troubleshooting techniques for the misfeed of automatic partition assembler insert machine?

1. partition assembly machine of the Latch Inserting Machine and Its Solution

(1) Observe whether the paper surface is flat. If there is paper jam in the insert, first check whether the surface of the printing paper is flat. If the paper is curled or folded, the paper with flat and smooth surface shall be used instead, and the printing paper surface shall be free of foreign matters.

(2) The paper is too thin or too much. The quality of printing paper shall be more than 60g. If the printing paper is too thin, it will make it difficult for checkers to move paper, and it is easy to cause checkers paper jam. And the printing paper loaded at one time cannot be too thick.

(3) Other solutions: The paper tray is improperly installed, and the paper quality is poor, such as too thin, too thick, and wet. It may also cause a paper jam or prevent paper removal.

2. Reasons and Solutions for No Paper Feeding of automatic partition assembler

(1) Too much printing paper is put in. First, check whether the installation of the printing paper meets the standard, for example, whether the loading position has exceeded the arrow mark on the left guide rail of the printer. If so, print paper must be reduced.

(2) The paper is wet. If the paper is stored for too long and the surface is wet, it may not feed. At this time, we need to dry the printing paper.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Dec-09-2022