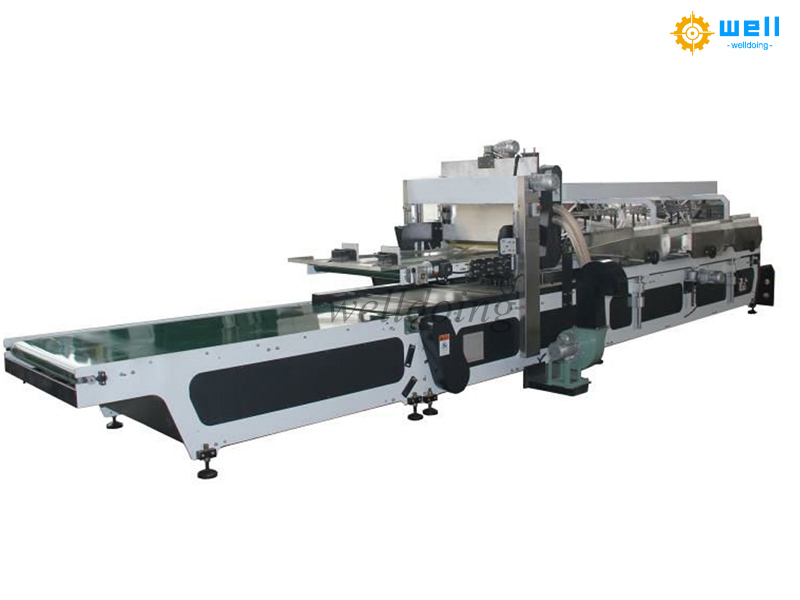

A cardboard partition assembler machine usually refers to an automated device used in the packaging process to accurately insert products into the predetermined cardboard box slots.

Generally speaking, the basic steps for operating a cardboard box inserting machine may include the following:

1. Check equipment status: Before starting the machine, all components should be visually inspected to ensure that there are no foreign objects, damage, or abnormal conditions.

2. Set parameters: Based on the size and characteristics of the product to be packaged, set the corresponding parameters of the machine, such as slot depth, speed, etc.

3. Loading raw materials: Ensure that cardboard boxes and other packaging materials are correctly placed in the designated area of the carton partition assembling machine .

4. Start operation: Start the full automatic partition assembler machine observe whether the initial operation is stable, and confirm that the robotic arm or insertion mechanism can accurately perform the task.

5. Monitor the production process: Continuously monitor during machine operation to ensure packaging quality and pay attention to any abnormal sounds or movements.

6. Shutdown and maintenance: After production is completed or maintenance is required, turn off the machine power for cleaning and necessary maintenance work.

The above steps are based on the operation process of general automated packaging equipment, and the specific operation of the cardboard box inserting machine may vary. Before operating a specific model, it is necessary to carefully read the operating manual of the equipment and the guidance documents provided by the manufacturer.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Sep-24-2024