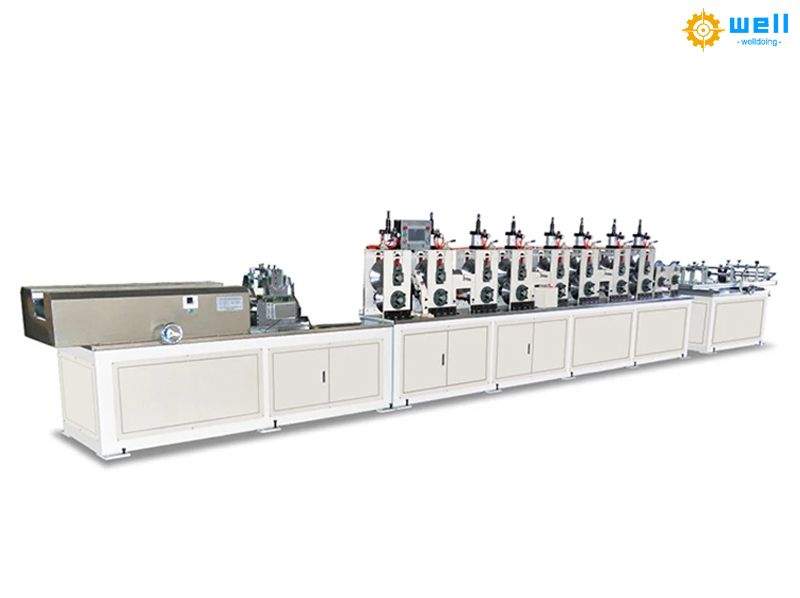

The size adjustment of paper corner protector machine equipment usually involves adjusting multiple components of the machine to ensure the final production of paper corner protectors that meet specific size requirements. The specific adjustment steps may vary depending on different models and brands of machines, but generally include the following aspects:

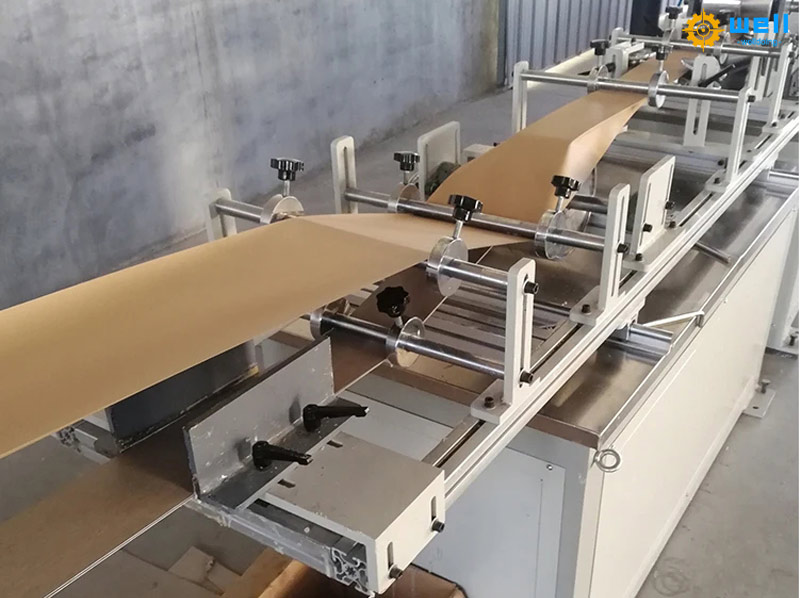

Adjust the paper guide section: Ensure that the paper is correctly guided into the machine, which usually involves adjusting the position and tension of the paper guide rollers.

Adjust the gluing and forming parts: Ensure that the paper is evenly glued and that the “V” shaped pressure roller in the forming part can accurately press the paper to the desired angle.

Adjust the cutting device: Set the appropriate cutting length to ensure accurate and error free cutting action.

Adjust size limit block: Set size limit blocks at appropriate positions on the machine to control the final size of the paper corner protector.

Calibrate the pressure roller: Adjust the pressure of the pressure roller to ensure that the paper corner protector obtains appropriate tightness during the forming process.

Fine tuning machine settings: Make small adjustments to optimize machine settings based on the actual size and quality of angle corner edge protectors making machine in production.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Nov-12-2024