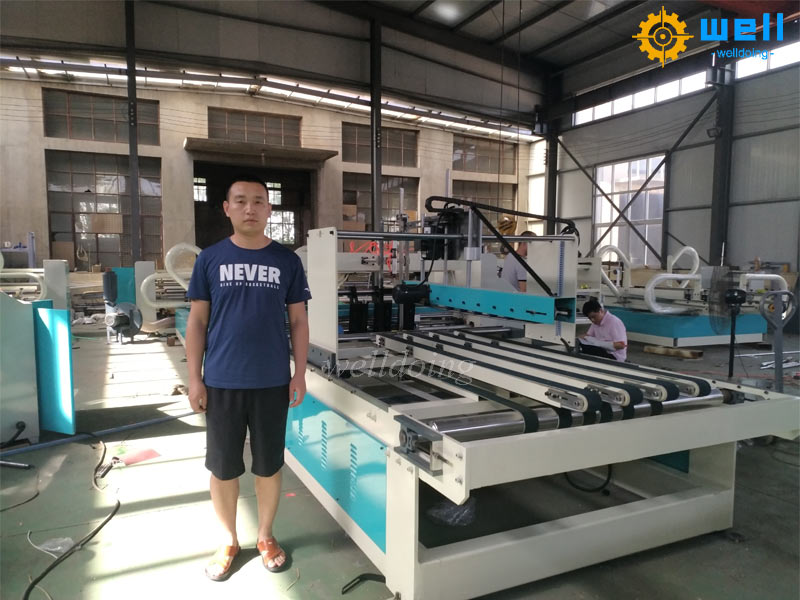

In order to fully realize its value, besides the functions of its own equipment, the maintenance of the cardboard box full auto carton gluing machine directly affects the productivity and financial issues of the enterprise.

A good maintenance of the box gluing machine is of utmost importance. Below is an introduction to the cleaning and lubrication issues of the box gluing machine maintenance:

1. The operation interface should be kept clean and the machine can be cleaned with dry cloth strips and detergent.

2. The inner plate support, shaft, and roller should be cleaned regularly, and a mixture of lubricating oil and butter should be used to better prevent rusting by shaking left and right.

3. Wipe the belt of the adhesive box machine with clean water to keep it clean and prevent slipping, especially to prevent it from sticking to the belt; Clean the bottom glue wheel and glue box after work every day, otherwise the glue inside the glue box of the High speed automatic folder gluer machine will freeze and affect the gluing effect.

4. The glue box of the gluing section should be kept clean and regularly wiped.

5. Clean the guide rod and ensure that there is no dust or dirt on it to avoid further wear. Do not use solvents such as Tena water and gasoline to clean it to avoid damaging the surface of the machine, or directly clean the machine with water to avoid rusting.

6. Lubrication of the cylinder: Check every shift whether the oil level in the oil cup of the air source processing element is sufficient. If not, please supply it in a timely manner. When the full automatic gluer machine is working, it is advisable to drop a small drop of oil in the oil window every time the box is sealed, and not too much to avoid oil stains. It is recommended to use specialized lubricating oil (ISO VG32 or equivalent) as the lubricating oil, and no other substitute oil should be added to prevent the blockage of the pneumatic circuit from causing faults. (Also: Each shift should check if there is too much water in the filter cup of the gas source treatment element, and the water in the filter cup should be discharged in a timely manner.)

7. Lubrication of guide rods and column groups: Use a brush to apply an appropriate amount of oil to each guide rail (as shown in the figure LP1-LP4) once a week, and start the machine to seal the box several times to evenly distribute the oil on the surface of the guide rail.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Oct-13-2023