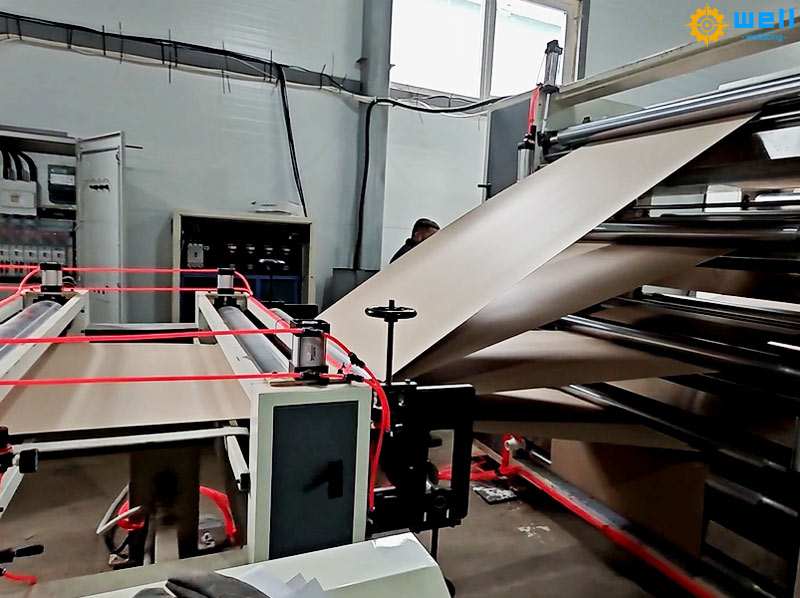

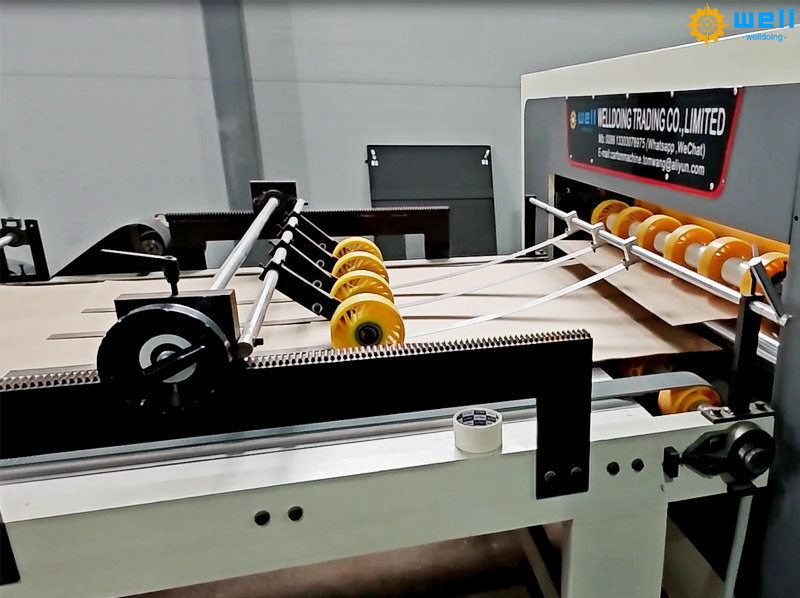

An automatic hardboard production line is an equipment used for producing cardboard, mainly composed of multiple components, including a paper rack, a bridge conveyor, a glue coating machine, a compactor, a drying plate dryer, a cooling section, a vertical and horizontal cutting machine, etc. These devices work together to process raw materials into cardboard, which is widely used in the production of packaging materials such as cardboard boxes, paper boxes, high-end gift boxes, stationery supplies, etc.

The maintenance points of the automatic paperboard production line include the following aspects:

Maintenance of mechanical transmission

1. Check the fasteners of the machine, such as the fixing screws, bearings, transmission shafts, oil cylinders, and oil pipe joints at the connections of various mechanical components, to see if they are loose.

2. Inspect the universal joint, maintain lubrication, and replace it promptly if wear is found.

3. Check the synchronous belt and chain, check the tightness of the belt, whether there are any cracks at the edges, whether the synchronous belt rack is worn, and whether the chain is short of oil. If there are any abnormalities, replace them in a timely manner.

4. Check the gearbox for any abnormal noise, normal gear oil level, oil leakage, and inspect the gears for any damage from the inspection port.

Inspection and maintenance of electrical appliances

1. Check if the machine operation buttons are loose, if the emergency stop is effective, and if the button terminals are loose. 2. After cutting off the power, check if the terminal wires are loose.

3. Check if the cooling fan of the drive is working properly, and clean the dust with compressed air that has been installed with an oil-water separator.

4. Check the maintenance of the cooling air conditioner and fan in the electrical cabinet, and inspect the filter screen for dust accumulation and heat dissipation.

Other precautions

1. Mechanical preheating and cooling must be carried out while in operation. If it is necessary to stop production, the power must be cut off and heated before stopping.

2. The glue roller and glue tank must be cleaned with clean water at the end of each shift.

3. The double-sided conveyor belt must be supported during production to prevent burns caused by high temperatures.

4. Regularly add high-temperature lubricating grease to the bearings of the grey hardboard making machine , regularly replace and add engine oil to the infinitely variable transmission of the reducer, and regularly add lubricating oil to the gears, sprockets, and chains.

5. When cleaning or removing paper scraps and adhesives from the surfaces of corrugated rollers, rubber rollers, pressure rollers, and various grooves, it is necessary to stop the operation to prevent the cleaning tools from getting stuck in the machine.

6. The edge material cut by the slitting knife should be straightened at the beginning to prevent it from getting caught in various axes. Once caught, stop and clean it to avoid injuring your hands.

7. Electrical control system: Before starting up, check the control circuit for any damage or leakage, whether the control box motor is damp, and whether there are any conductive materials entering to prevent short circuits and prevent the machine from starting up.

The above maintenance points are based on the information in the search results, and the specific maintenance operations may vary depending on different production line models and production environments. Therefore, it is recommended to refer to the equipment’s operation manual and the maintenance guidelines provided by the manufacturer when performing maintenance operations.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Dec-11-2024