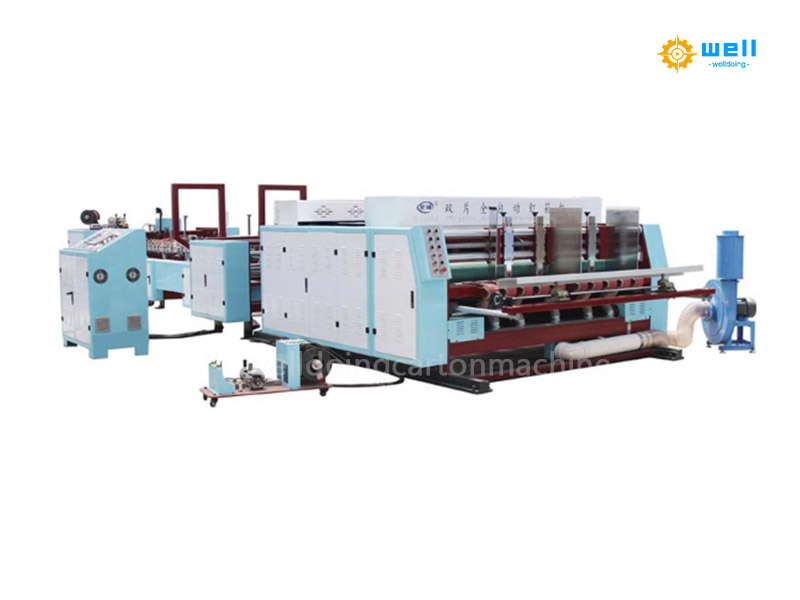

The practical fully Automatic carton folding gluing stitching machine consists of six parts: paper feeding section, wire collision section, folding section, nail box section, counting output section, and electrical control section.

This machine adopts PLC control touch screen input data, and the nail box action servo motor control, with simple and reliable operation. Automatic paper feeding, automatic line touching, automatic folding, automatic correction, automatic nailing, automatic counting, automatic stacking output, whole machine front and back, synchronous adjustment, order storage, distinguishing the working disadvantages of the gluing machine and the gluing machine during installation. The main machine separates the corrugated folder gluer stitcher machine from the gluing machine, with one click conversion, left and right lateral movement, and operates independently during gluing work, making adjustment more convenient, fast, and efficient. Advanced technology and reliable quality.

The advantages of the nail box part of the fully automatic nailing folding gluing equipment

1. The automatic folding gluing nailing machine head is made of special materials, which are wear-resistant and not easily damaged.

2. The characteristic of this machine is that the head is directly driven by a servo motor, with stable and accurate speed.

3. The nail thread adopts two 20kg large flat wire automatic feeding devices at a time, reducing the number of wire changes and improving production efficiency.

4. This machine can perform multifunctional operations on cardboard boxes, including single nail, double nail, reinforced nail, and head and tail nail.

5. The nail speed can reach 700 nails per minute.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Jun-28-2024