- corrugated carton Printer slotter die cutter machine

- hardboard production line

- partition assembler machine

- carton folder gluer machine

- Ink Waste Water Treatment Machine

- paper angle board machine

- paper making production line

- Box stitching machine

- Paper tube making machine

- paper making production line

- Full automatic die cutting machine

- Slotting machine

- stacking machine

- thin blade machine

- Paper coating machine

-

semi automatic flat bed die cutting machine

1. PLC control, safer and more reliable.

2. equipped with various safety protection devices.

3. Imported parts, more accurate control.

4. Bearings and electrical parts with reliable positioning and accurate control.

-

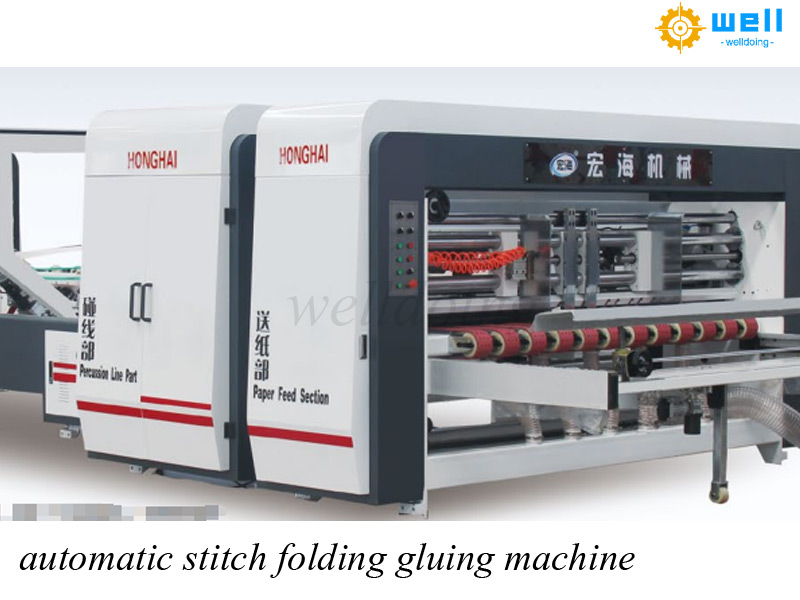

automatic carton box nail folding gluing equipment

1. parts:

paper feeding part, line touching part, folding part, nailing box part, counting output part and electrical control part

2. Automatic feeding, automatic line, automatic folding, automatic correction, automatic nailing, automatic counting, automatic stacking output

3. when the adjustment more convenient, fast and efficient

4. Advanced technology, reliable quality.

-

Semi automatic die cutting machine with stripping section

1. Adopting the worm gear transmission mode.

2. the unique waste cleaning device

3. photoelectric detection device, safe and reliable

4. Adopting central positioning system

-

Semi automatic die cutting machine

1. PLC control, safer and more reliable.

2. equipped with various safety protection devices.

3. Imported parts, more accurate control.

4. Bearings and electrical parts with reliable positioning and accurate control.

-

semi automatic die cutting creasing machine

1. PLC control, safer and more reliable.

2. equipped with various safety protection devices.

3. Imported parts, more accurate control.

4. Bearings and electrical parts with reliable positioning and accurate control.

-

double chip automatic box stitching machine

Name: Double chip full automatic box stitching machine Model: SQDJ-2500 Mechanical speed: 700-800 nails per minute; Applicable to corrugated board three layers, five layers, seven layers (seven layers need special instructions).

-

automatic carton box folder gluer stitching machinery

1. parts:

paper feeding part, line touching part, folding part, nailing box part, counting output part and electrical control part

2. Automatic feeding, automatic line, automatic folding, automatic correction, automatic nailing, automatic counting, automatic stacking output

3. when the adjustment more convenient, fast and efficient

4. Advanced technology, reliable quality.

-

automatic corrugated box folder gluer stitcher machine

paper feeding part, line touching part, folding part, nailing box part, counting output part and elecrical control part. PLC control touch screen input data, nail box part action servo motor control, simple and reliable operation. Automatic feeding, automatic line, automatic folding, automatic correction, automatic nailing, automatic counting, automatic stacking output, before and after the whole machine

-

Manual double servo stitcher machine

1.Schneider france original import four servo motor drive ,high precise with few mechnical driving part ,reduce the machine damage

2.box stitching machine wenlun touch screen ooperation the parameter ( nail distance, nail unmber,nail types,tial gate ) change convinently

3.The box stitching machine control system use the omron plc control system -

full automatic die cutting machine

1. adopting the central positioning system

2. Equipped with full waste cleaning device

3. adopting the central positioning system and pneumatic locking plate device

4. The computer monitoring display system and 3D touch screen operation

5. The high-speed precision leading edge paper feeding device

-

automatic corrugated stripping and die cutting machine

1. adopting the central positioning system

2. Equipped with full waste cleaning device

3. adopting the central positioning system and pneumatic locking plate device

4. The computer monitoring display system and 3D touch screen operation

5. The high-speed precision leading edge paper feeding device

-

Fully automatic pizza box die cutting machine

High Quality Service:

- Provide round-the clock telephone counseling services.

- For the user’s service requirements, will answer and come up with solutions in the shortest possible time.

- Service staff is at any time on standby for customers to solve all kinds of difficult problems.

- Provide free installation and adjustment, service staff will inform to customers how to maintain the machine.

- Have our equipment, will enjoy a one-year warranty and life-long maintenance.