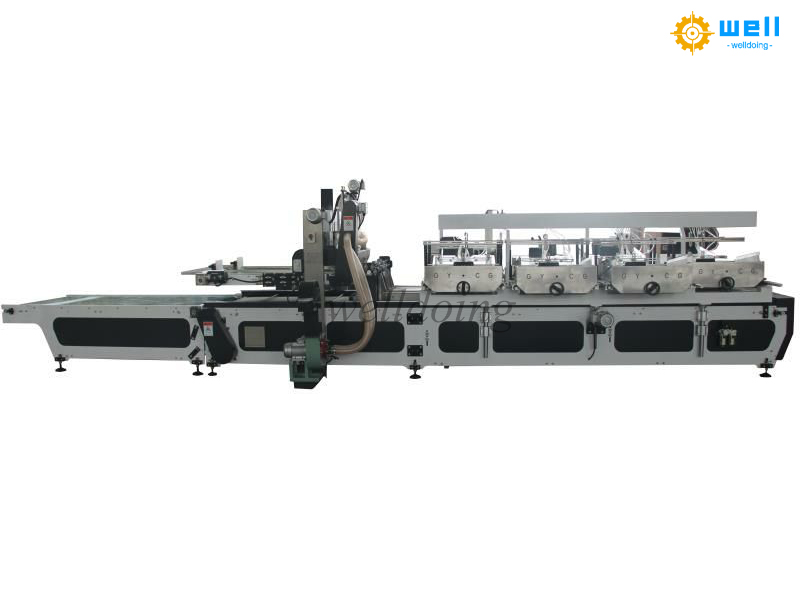

thin blade machine - Welldoing trading limited

Brief introduction Corrugated cardboard thin blade slitter

Corrugated cardboard thin blade slitter machine widely used in carton box making machine .Thin balde slitter machine function is slitting corrguated paperboard to narrow pieces and creasing bending line for carton box making . Slitting blade and creasing wheels can be made according to customer request

Corrugated cardboard thin blade slitter main structure

Main frame, work table, edge frame for paperboard support , crimping device, electrical control system,air pump (customer-supplied)

Thin blade slitter characters

1.Can set the qty. of paperboard, automatic stop the feeding after finishing.

2.Auto suction feeding, assured the safety of workers and decreased the working load.

3.Suitable to a large scale paperboard machining.

Electric adjusted blades

Corrugated Cardboard Electric Adjustment Thin Blade Slitter Score Machine

Automatic feeder Department:

Cardboard size adjustment using screw adjustment mechanism, one person operation, easy and quick.

Easily adjustable yards paper structure to better adapt to a variety of cardboard length and feed stable and accurate.

Feed belt made of high quality imported rubber seamless belt, friction, long life.

Slitting Department:

BFY-8 Series thin knife slitting creasing machine adopts thin knife slitting, after grinding wheel after sharp blade makes cutting the cardboard edge finishing, flattening phenomenon is minimal, improve quality and appearance of cardboard overall quality especially in favor of cardboard printing after feeding, thereby reducing waste, improved quality of the carton.

Sharpener with manual and automatic switching of two ways, according to the time or paperboard running speed selection sharpener and stop grinding time. To keep the blade sharp and make cardboard cut smooth and tidy;

* Adjust the blade from electric, pneumatic automatic locking fixation. Manually adjust the pressure line width. Using separate single-handedly carrying knives structure, according to the number of cardboard cut switch; program the machine wear and tear caused by different cutter size can be adjusted.

Features:

The plastic shaft feed, after cutting, and then plastic shaft feed, the last pressure line forming, after the process used when the clear indentation depth of cut paper with high steel knife blade drive belt drive, when replacing blades can be quickly set up for using plastic shaft pull paper, pull the paper toward the same equipment than the one higher than a chip.

Technical parameters:

|

Spec |

Data |

|

Machine allows cardboard width (width) |

2300mm |

|

The maximum mechanical speed: |

150 m / min |

|

Paper Cutter |

(according to user requirements increase or decrease) 4 pieces |

|

pressure line Round: |

(according to user requirements increase or decrease) 6 pairs |

|

Minimum slitting width: |

140mm |

|

Minimum pressure line width: |

30mm |

|

outer diameter of paper thin blade: |

200mm |

|

paper thin blade thickness: |

1.3mm (alloy) |

|

Main motor power: Fan power: |

5.5kw 3.4kw |

|

Air pressure: |

<0.4mpa |

|

Machine dimensions: |

3400 × 2300 × 1500mm |

|

Weight: |

1600kg |

|

Min.Feeding: |

(two plastic wheelbase) 320mm |